Achieve the

Extraordinary

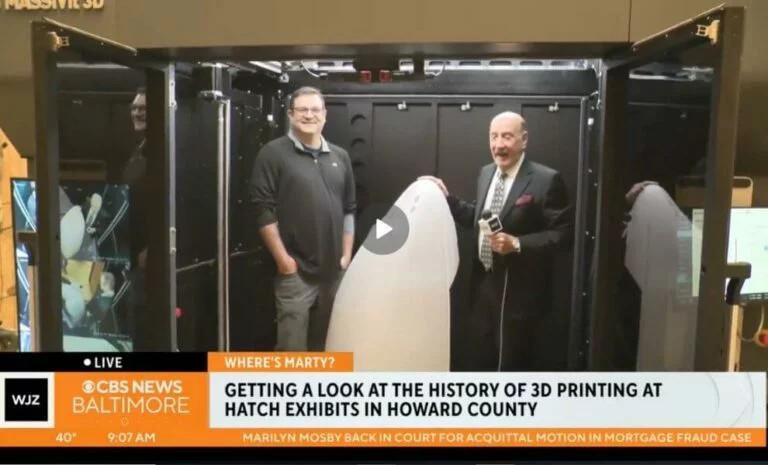

Industrial 3D Printers for Next-Gen Manufacturing

Massivit’s advanced additive manufacturing systems allow you to automate production of large parts to take your business to the next level. Print industrial, custom components at unprecedented speed.

Industrial 3D Printers

MASSIVIT

10000

Automate your Mold Production for Composites

The Massivit 10000 additive manufacturing system dramatically speeds up mold production for composite materials manufacturing. Directly print industrial molds, plugs, tools, jigs, and fixtures within a matter of days instead of weeks. Minimize waste and cut down on labor costs.

MASSIVIT

5000

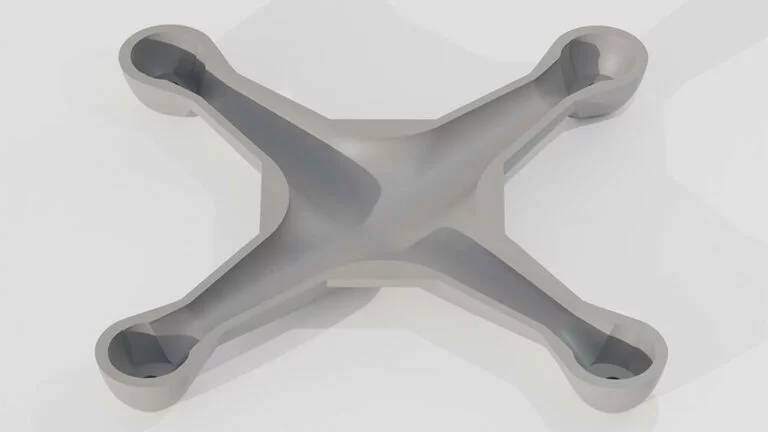

Print Large Industrial Parts Extra Fast

The Massivit 5000 industrial-grade 3D printer enables full-scale, custom manufacturing and functional prototyping. Print large, custom components for automotive, marine, and railway applications at unprecedented speed. Cut costs and reduce waste.

MASSIVIT

1800

Expand your Business with Ultra-Fast Production of Large Parts

The Massivit 1800 3D printer empowers fabricators to produce large, complex parts and mockups up to 1.8m (70in.) with ease. Enjoy design freedom, shorten your lead times, and gain a competitive edge with this this scalable large 3D printer – already adopted in over 40 countries.

Materials

Advanced 3D Printing & Casting Materials

Massivit’s high-performance printing and casting materials enable high-speed custom manufacturing, tooling, and prototyping. Learn more about Massivit’s collaboration with Sika to co-market advanced digital tooling materials.